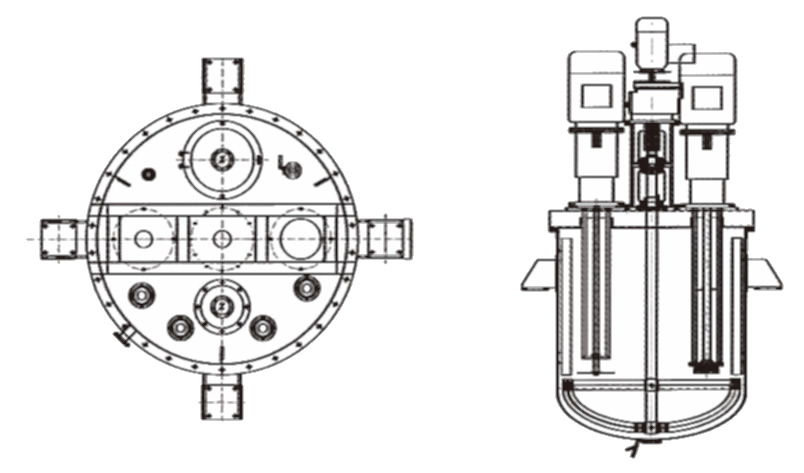

Working principle of high shear kettle

Fill the kettle with enough liquid, start the motor, and its shaft drives the turbine to rotate. At this time, an upward suction force is formed at the lower inlet of the stator to allow the material to enter the homogenization head.

The material is subjected to high-speed impact, compression, shearing, and friction for the first time inside the homogenization head. When spraying horizontally through the special holes of the stator, the material is subjected to a second high-speed impact, compression, and shearing.

The horizontally sprayed material generates radial flow and axial displacement inside the homogenization kettle, and at this time, the material is subjected to a third impact. Due to the mutual impact and displacement of the two flows horizontally, and the cross mixing and shearing with the radial flow, the flow inside the kettle generates a bidirectional hyperbolic large circulation vortex, avoiding blind spots caused by the difficulty of inhaling the upper material. Emulsification homogenization is more thorough and efficient.

characteristic

High shear gauges are made of materials that match the raw materials inside the gauge, such as carbon steel, stainless steel, and nitriding steel, to ensure that the equipment can adapt to various occasions such as acid resistance, alkali resistance, wear resistance, and high temperature resistance. Adopting bidirectional suction in the structure to improve material dispersion and adapt to various fineness requirements Configure a frequency converter to achieve stepless speed regulation.

application area

Widely used in the PCB industry for adhesive manufacturing, as well as in petrochemical, coating, ink, dye, food, pesticide, daily chemical and other fields.

Technical Parameter

|

model |

Emulsifier power (kw) |

Emulsifier speed (rpm) |

Frame mixing power (kw) |

Frame mixing speed (rpm) |

Processing capacity (L) |

|

ZS-GJ501 |

1.1 |

2900 |

1.1 |

30~65 |

50~100 |

|

ZS-GJ505 |

4 |

2900 |

1.5 |

30~65 |

100~200 |

|

ZS-GJ510 |

7.5 |

2900 |

2.2 |

30~65 |

500~1000 |

|

ZS-GJ525 |

18.5 |

1470 |

5.5 |

30~51 |

1000~2000 |

|

ZS-GJ530 |

22 |

1470 |

7.5 |

30~51 |

1500~3000 |

|

ZS-GJ550 |

37 |

1470 |

11 |

30~51 |

2000~5000 |

pour:

● The upper limit processing capacity in the table refers to the data measured when the medium is "water".

● The data is subject to change without prior notice, and the correct parameters shall be based on the actual product provided.

● Special design and manufacturing can be carried out.