Characteristics of viscosity control system

Characteristics of viscosity control system

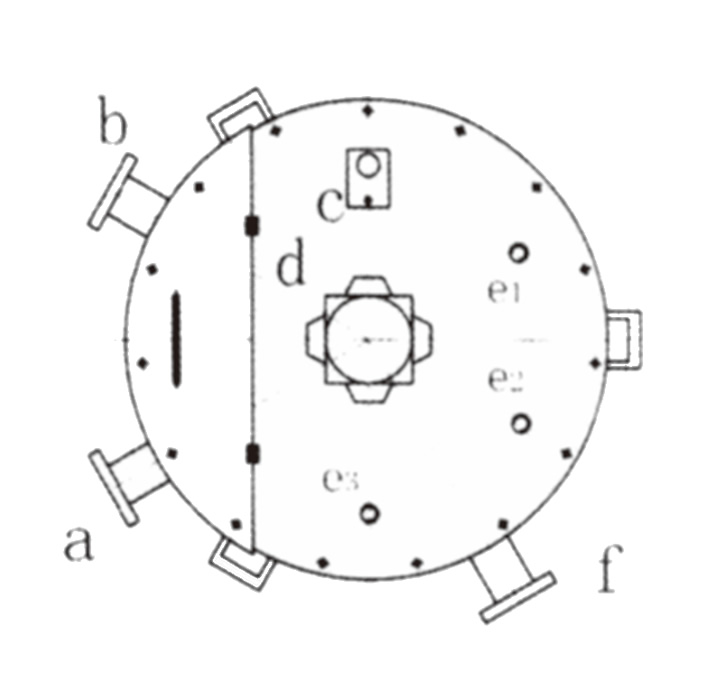

The viscosity sensor is used to detect the viscosity online throughout the process, and the high and low liquid levels of the viscosity tank are used to control the input and output, replenishment, alarm and other signals. The internal mixer adopts frequency conversion or pneumatic speed regulation, and different speeds can be selected according to different processes and viscosities. Using imported viscosity control instruments to improve the quality of adhesive viscosity control, reduce waste and defective products, lower production costs, and enhance customer economic benefits.

The control system is as follows:

● Add solvent control to viscosity tank

● Viscosity Nuo high liquid level alarm control

● Viscosity sight glue control

● Glue tank replenishment control

● Solvent Nuo Bu solvent protection system

● Low level groove adhesive replenishment control

purpose

Widely applicable for viscosity blending control of adhesive liquids in the PCB industry, as well as viscosity blending control of raw materials in industries such as coatings, fuels, oil alliances, papermaking, adhesives, pharmaceuticals, and chemicals.

Technical parameters of viscosity mixing tank

|

model |

stirring power (kw) |

stirring speed (rpm) |

Processing capacity (L) |

|

ZS-ND501 |

1.1 |

30~400 |

50~100 |

|

ZS-ND505 |

1.5 |

30~400 |

100~500 |

|

ZS-ND510 |

2.2 |

30~400 |

500~1000 |

pour :

● The upper limit processing capacity in the table refers to the data measured when the medium is "water".

● The above specifications are for reference only. The correct parameters are subject to the actual product provided.

● Special design and manufacturing can be carried out.