High-speed super-fine zirconia mixing ball mill, integrating dispersion, mixing, grinding and milling into one is a type of wet ball mill. The zirconia, on account of its high hardness, strength, toughness and even higher abrasion resistance and chemical resistance, is manufactured into a stirring rod functioning dispersion and mixing to facilitate the movement of zirconia balls so as to develop a grinding group, thus fully grinding the materials into those with particle size of 1u or even finer. The zirconia rod and zirconia balls, by moving in circles with the mixing may produce stable and high-quality products finally.

This equipment consists of a medium-speed mixer, a mixing kettle and a heating jacket.

The ball mill is a high-efficiency machine for continuous production or circular process of fine materials. It is the motor to drive the spindle to move in medium speed. The parts which may contact with the materials are made of zirconia, therefore, it may be applied to mill super-fine liquid particle materials. The xirconia rod is used for impact crushing, and the zirconia ball is used for grinding and crushing. Such equipment is perfect for high-viscosity grinding. Its mixing system is composed of explosion-proof motor, belt pulley,spindlle, bearing bracket and mixing rod, etc, and in general, it runs with the speed of480r/min.equivalent to 8-10m/s at the end of the mixing rod.

Application area

This equipment may be widely used in industries of physics, chemicals, geological mining, soil, metallurgy, electronics, electricity, materials, chemical light industry, pharmacy, cosmetology,environmental protection, ceramics and glasses, etc. Specifically, it may be applied for milling of fillings for CCL (copper-clad plate) industry, electronic ceramics, structural ceramics,magnetic materials, LCO (lithium cobalt oxide),LMO (ithium manganese oxide),printing ink, paint, coatings, fillers, catalyst, phosphor powders, fuel cells, ceramic capacitor, valve disc of arrester, ceramic filter, medium ceramics and zinc oxides, etc

Product characteristics

● The user may use proper super-fine ball mills according to the technological requirement of the user, the working condition, the industry and the capacity.This equipment, with the assistance of zirconia mixing rod with high rotary speed and the small zirconia balls working as the medium, may improve the milling efficiency and the performance; hence, it may satisfy the technological requirement concering the particle size of materials and also may evenly distribute the particle size. In the area of preparing sub-micron powders by means of mechanically milling, this ball mill shall be an advanced and proven one.

● It has reasonable height-diameter ratio of the barrel body, proper configuration of driving power and strong super-fine miling capacity.

● The equipment is controlled by converter program of AC motor and is integrated all parts into one,thus producing low noises occupying small spaces and having stable operation

●Leakage may be prevented by the application of multiple sealing products such as PTFE gasket and skeleton seal, etc

● The jacket (optional) may be used to circulate the cold/hot water to preserve the heat of or cold the materials.

Operating principle

The equipment applies vertical structure, and its zirconia rod, by the powerful diving force, may mix the materials and mill balls perfectly, thus realizing the dispersion and blending of them,and the balls and materials in the barrel, through high-speed collision, crushing and abrasion, may be evenly blended ground and milled. Compared with the traditional drum ball mill, it has higher efficiency. The materials may be milled by the machine repeatedly.

Model and technical parameters

|

Molde

|

Rated

output

(L,H20 )

|

Output

RPM

(rpm)

|

Motor

power

(

kw)

|

Molde

(mm

)

|

Outlet

size

(

mm)

|

|

ZSQM-100

|

100

|

300-500

|

15

|

DN50

|

DN25

|

|

ZSQM-150

|

150

|

300-500

|

22

|

DN50

|

DN40

|

|

ZSQM-250

|

250

|

300-500

|

37

|

DN50

|

DN50

|

Note :

● The medium used for the determination of the above output is water.

● The output depends on the viscosity of materials and the quality requirement of final products.

● The data in ths Table maybe be altered for technological improvement or customization; therefore, that of products in kind shall prevail.

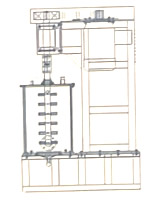

Mounting dimension

|

Model

|

Power kW

|

Rotating speed rpm

|

A

|

B

|

C

|

D

|

H

|

n-d

|

|

ZSQM-100

|

15

|

300-500

|

1500

|

600

|

2400

|

500

|

700

|

12-F18

|

|

ZSQM-200

|

22

|

300-500

|

1600

|

700

|

2500

|

550

|

900

|

12-F18

|

|

ZSQM-250

|

37

|

300-500

|

1700

|

800

|

2650

|

600

|

1000

|

12-F18

|

● The data stated in this. table are only for reference and that of products in kind shall prevail.