Magnetic Base:

Magnetic Base:

On site metallographic sample preparation matching (optional):

On site metallographic sample preparation matching (optional): On site metallographic image analysis and imaging system (optional)

On site metallographic image analysis and imaging system (optional)Configure FMIA2023 genuine metallographic analysis system and WiFi wireless camera to achieve functions such as on-site image acquisition, metallographic structure analysis, and metallographic detection report generation.

Technical parameters of portable metallographic microscope:

| Standard host configuration | Whole machine model | ||

| component | specifications | BXJ-1 | |

| optical system | Limited distance chromatic aberration correction optical system | ● | |

| observing tube | Monocular observation tube. | ● | |

| eyepiece | Wide field of view WF10X (Φ 18mm) | ● | |

| objective | Long distance flat field achromatic objective lens:PL L 10X/0.25 WD8.8mm | ● | |

| Long distance flat field achromatic objective lens:PL L 40X/0.6 WD3.73mm | ● | ||

| Lighting System | 6V3W LED Lamp illumination, rechargeable lithium battery | ● | |

| base | X-Y Magnetic base, fast non-magnetic base | ● | |

| Optional configuration | |||

| Scheme 1 | Portable metallographic microscope standard host |

|

O |

| FMIA2023 Genuine metallographic analysis software | |||

| 500 Ten megapixel Sony chip camera device | |||

| 0.5XAdapt mirror interface | |||

| High precision micrometer | |||

| Scheme 2 | Portable metallographic microscope standard host |

|

O |

| FMIA2023 Genuine metallographic analysis software | |||

| WIFI camera | |||

| 1X Adapt mirror interface | |||

| High precision micrometer | |||

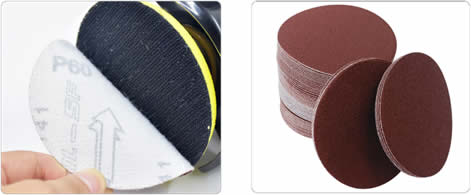

| sample preparation equipment | Bosch angle grinder, Bosch special carrying case, sandpaper, wool felt, diamond polishing agent, etc | O | |

Note: "●" is the standard configuration; 'O' is an optional item

FMIA2023 Introduction to genuine metallographic analysis software

The FMIA2023 metallographic image analysis software system is developed by our company based on the current needs of casting enterprises, automotive parts enterprises, heat treatment enterprises, bearing steel industry, power system industry, railway parts industry, and various related testing companies for metallographic testing, in order to improve product qualification rate and assist in the improvement of laboratory inspection level. We collected the opinions of experts and teachers from various industries to develop this FMIA2023 metallographic image analysis software system.

The software system national standard library contains 150 categories and approximately 700 commonly used sub modules, which basically cover commonly used metallographic standards and meet the requirements of metallographic analysis and inspection in the vast majority of units. Specify open related categories according to the needs of different industries to meet industry testing requirements. Lifetime free access to all modules and lifetime free upgrade of standards.

Given the continuous increase in new materials and imported grade materials, materials and evaluation standards that have not yet been entered into the software can be customized and entered.

Software installation is more intuitive and concise

The new software installation, registration, and calibration guidance mode is simple and clear, and can be completed through default prompts.

Genuine Software Assurance System

After the software installation is completed, the first step is to activate the genuine software, followed by registering the computer hardware ID to ensure the legitimate rights and interests of the customer.

Requirement standards can be customized

In addition to the standard testing module, customized testing modules can be customized according to customer needs, such as enterprise standards, special industry standards, etc.

Quick entry for 7 major inspection categories

Quick entry to 7 major categories of statistical production: grain size, non-metallic inclusions, microstructure of steel, decarburization layer analysis, gray iron, ductile iron, carbon steel spheroidization, etc., plus a metallographic teaching.

The report template can be modified

We can customize report templates for different enterprises.

Genuine software can be upgraded

According to the implementation time of the National Standardization Committee standards, free software upgrades will be carried out.

Widely applicable to computer systems

This software can be installed and run on Windows 7 and Windows 10

Sample production and operation steps:

Operation steps: Implement according to the metallographic sample preparation requirements of GB/T13298-2015.

Preprocessing: Use an "angle grinder" to roughly grind the metallographic parts that need to be tested with an angle grinder grinding wheel: remove the oxide scale and perform surface treatment.

Sample polishing: Sample polishing: Use an "angle grinder" to replace the finely ground area with a polishing wool felt, spray diamond polishing agent onto the finely ground area, and polish the sample with wool felt.

Metallographic testing: Polish the workpiece into a mirror surface, and perform metallographic corrosion on the workpiece according to the metallographic corrosion method of the material. Place the corroded sample in a portable metallographic microscope to observe the metallographic structure.

Packing list for portable metallographic microscope:

|

Serial Number |

name |

configuration |

|

1 |

Metallographic microscope host |

Host: 1 unit |

|

Eyepiece WF10X/18mm: 1 piece |

||

|

Long distance flat field achromatic objective lens: 1 each for 10X and 40X |

||

|

2 |

Genuine metallographic analysis software (optional) |

Software encryption lock, driver USB flash drive, high-precision micrometer: 1 each |

|

3 |

WIFI camera (optional) |

WIFI camera, charging head, data cable: 1 each |

|

Industrial camera (optional) |

5-megapixel Sony chip camera device, etc. |

|

|

4 |

Polishing equipment (optional) |

Angle grinder: 1 set (including Bosch original toolbox) |

|

Sample preparation consumables: adhesive disc, wool wheel, sandpaper, diamond spray polishing agent |